Additive Manufacturing

Since 2006, Valland has been active in the field of design and production of industrial Oil and Gas valves, custom made according to our customers' requirements. Since the beginning of Valland, our main area of activity has been non-standard products.

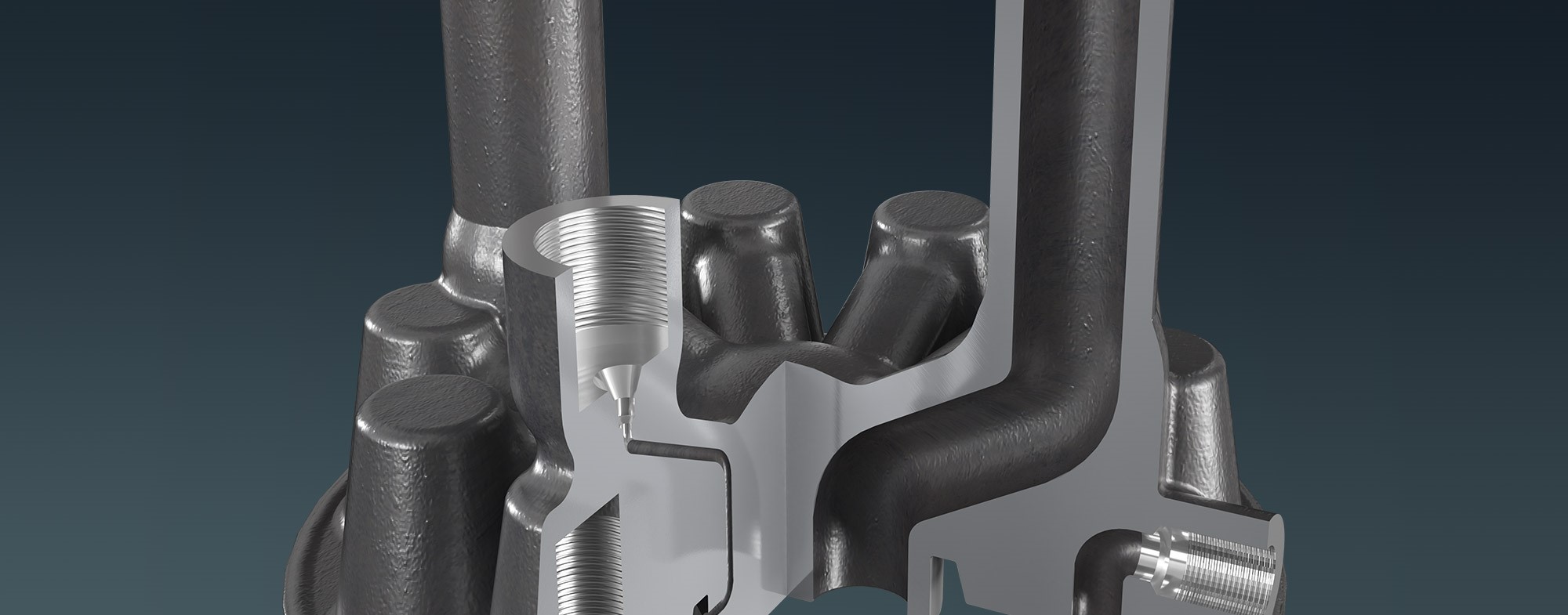

For this, Valland has been experimenting with additive manufacturing technologies since 2016, both metallic (Binder Jetting, Powder Bed Fusion, WAAM) and polymeric (FDM of pure and composite materials, hot-chamber FDM 3D printers for high-performance technopolymers, and photopolymerization of resins).

The activities, initiated with the support of external partners, have opened new opportunities in synergy with our core business (which remains engineering and manufacturing of industrial valves) for the production of components both for Oil and Gas valves and for new applications in the broader Energy and Design world.

Valland is also in the process of acquiring a new laboratory-scale hybrid technology atomizer (VIGA + Plasma) to develop new R&D projects and produce raw materials (powder for use in additive manufacturing) from traditional manufacturing scraps and by-products for use internally or for sale.