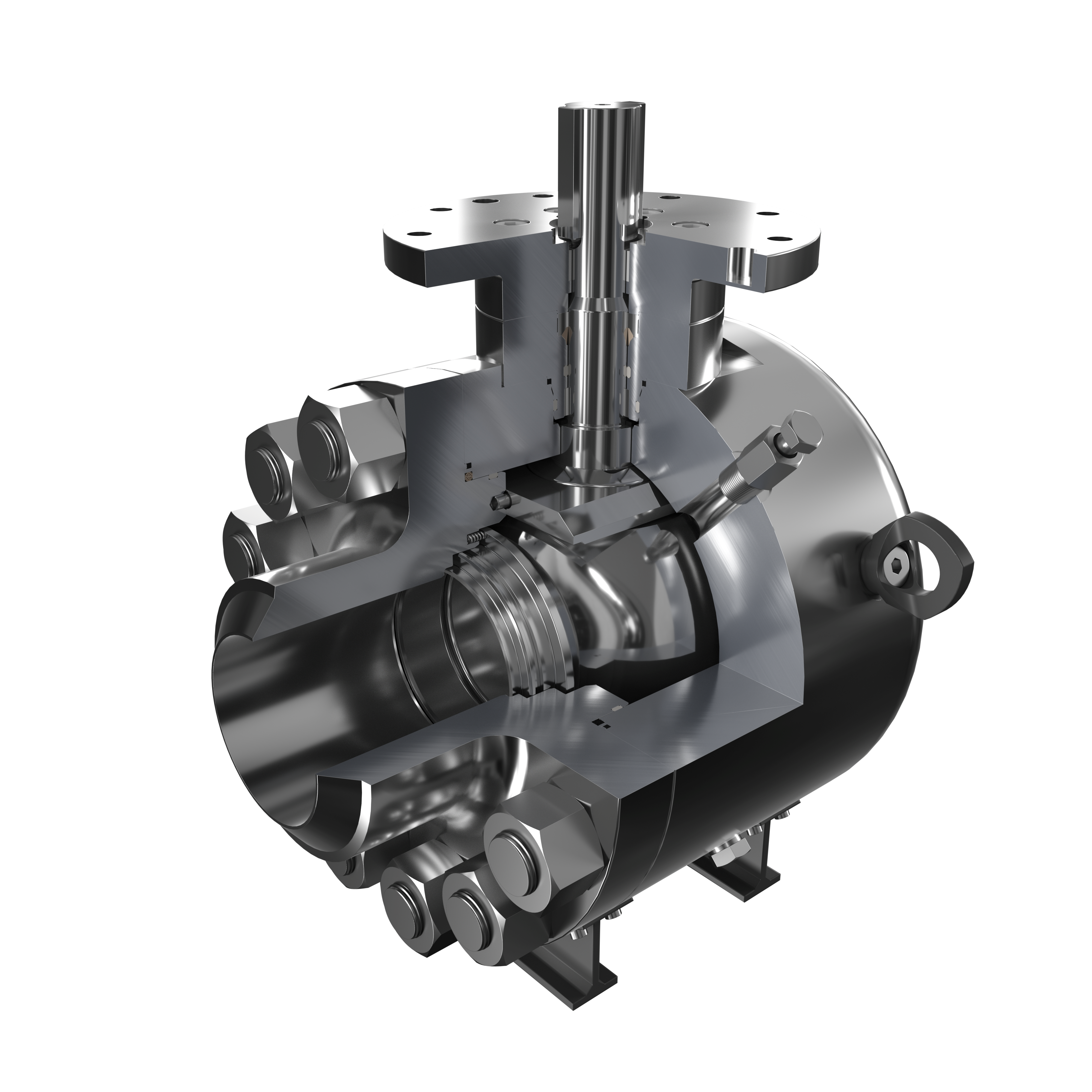

Trunnion

model H11 (Hydrogen)

| Applicable standards | API 6D Design according to ASME B1634 or ASME VIII Div. 1 & 2 |

| Pressure Class Range | ANSI Class 150 lbs. to 4500 lbs. |

| Size Range | API 6D - from 1/2" to 42" |

| Ends design | Flanged (RF/RTJ) - ASME B165, ASME B1647 or MSS SP-44 Flanged (6B/6BX) - API 6A Compact (i.e. Norsok Standard L-005) Butt-Weld (ASME B1625) and/or Butt-Weld + Pipe Hubbed according to client Clamp Special client's requirements |

| Body Design | Two Pieces |

| Closure Design | Bolted Closure or Fully welded |

| Ball support | Trunnion (small sizes < 4") - Support Plates |

| Seat design | Floating Self-Relieving - Floating Double Piston Effect Soft Sealing - Metal to Metal (c/w hardfacing) |

| Valve operation | Manual: Lever or Gearbox Actuated: Pneumatic / Hydraulic / Electric / Electro-Hydraulic |

| Available Materials | UNS S31600/3, UNS S31254, UNS S20910 and UNS S66286. Proper material selection verifed by Valland material experts. NACE MR0175 according to client request. |

| Additional Features | Double Block and Bleed, Double Isolation Barrier (DIB), Anti Blowout Stem, Antistatic Device, Special gasket to avoid contamination from environment. |

| Testing and Certification | Testing: High Pressure Gas, Pneumatic and Functional Test in hydrogen environment according to client specifications API 598 - API 6D Fire testing: API 6FA, API 607, BS 6755 part 2, ISO 10497 Fugitive Emission Test: ISO 15848 - 1 & 2 SIL Certificate up to SIL 3 TR-CU PED 2014/68/UE ModH - UKCA - TSG (upon request) |